Technology and 3D Tools Transform Concrete Construction Workflows. Find out what the Construction Process of

Tomorrow Looks Like.

|

Mr. Paul Wallett |

Amidst the Covid-19 gloom, there is finally good news on the horizon for the infrastructure and construction sector. The Indian government has rightly identified infrastructure and construction as priority sectors for investments in order to bounce back from the widespread economic recession that the pandemic has led to. This year’s budget has proposed `5.56 lakh crore capital expenditure for infrastructure, which represents a 34.5% increase over last year.

The ball is now firmly in the court of construction companies and as they gear up for accelerating the completion of projects both big and small, they can count on cutting-edge construction technologies as their ally. In fact, the ever-growing pressures for faster completion of all projects – from residential and commercial complexes to flyovers, highways, and airports – have necessitated the adoption of digital solutions to streamline workflows.

Nowhere is this adoption more critical than in concrete-based construction projects. Concrete is after all the most widely used construction material in India – and our nation is the second largest cement consumer in the world after China. It is the de-facto construction material of choice for most types of projects: from independent houses to tall residential complexes, from schools and hospitals to bridges and airports, and from metros to roads and highways.

Modern construction technologies, techniques and workflows have today emerged as powerful accelerators and enablers of efficiencies in all concrete-based construction projects. Still, the use of 3D modeling is perhaps the most important parameter that is key to improving overall project efficiency. There are many ways in which 3D tools transform the concrete construction process, and they can be pinpointed one by one, but the combined value of these tools is far more than the simple sum of its parts.

From pour planning to formwork and rebar, every step of the way is improved by working directly from a digital clone of the planned building, in the form of a 3D model, with manual tasks automated where possible.

Build it Virtually, Then Build it in Real Life

A constructible 3D model is the most realistic visualization of a concrete building before construction begins as it can highlight design inconsistencies before a single brick or slab is laid. 3D tools make it possible to create a full digital clone or a twin of the project that is being built, letting engineers and contractors work with accurate information instead of having to use guesswork for dimensions and element relations as with drawings and other documents

By using a precise digital clone of a building, concrete contractors are able to get the right dimensions and quantities calculation right the first time. A complete visualization without ambiguity transforms the project’s construction process because it eliminates the need for interpretation.

Further, each stakeholder involved in a project, from designers to structural engineers, from MEP contractors to fabricators, has access to all the information included in the model at all times. Because the model is digital, it is always up to date with the latest changes made by project owners. The digital 3D clone also allows everyone to view the building plan as it is at any stage, add information to it and extract information from it.

This makes the process as comprehensive as possible, because each stakeholder can base their work on much more data than if they were working individually. Information flows not just linearly, but seamlessly among all stakeholders. The result is a quality outcome, based on educated calculations and decisions. And when misunderstandings and rework are a thing of the past, productivity naturally goes through the roof.

A Fully Digital Workflow is Easier Than Ever

The integration of 3D tools into the concrete construction process has the potential to completely transform project workflows from beginning to end. However, and most importantly, it doesn’t mean that construction professionals will have to completely change their ways of doing their work or learn new things.

It actually means simply replacing manual tasks with automated ones and having a more intuitive, comprehensive and information-packed model to work from. The result is a streamlined process that benefits each and every construction professional and stakeholder, and a completed project that corresponds to the client’s needs and required standards in the best possible way.

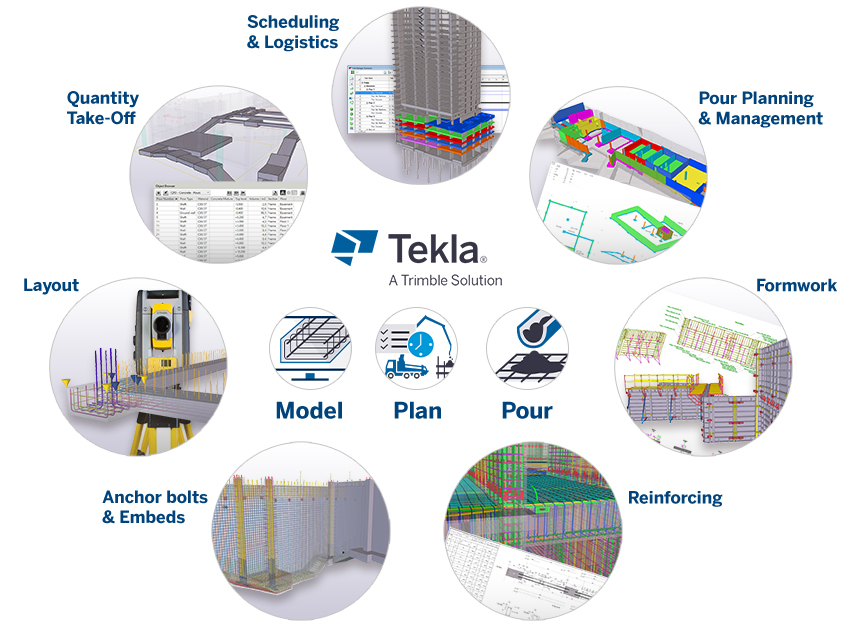

This integration is made easier with modern 3D tools like Tekla Structures, Trimble’s flagship modelling software for the construction industry. Tekla Structures offers 3D Building Information Modeling (BIM) right out of the box for concrete contractors and precast concrete producers.

The software generates digital 3D models (clones or twins) that are truly constructible and are purpose-built for the needs of concrete construction. As a case in point, Tekla Structures creates 3D models of pour information management, plan placement, quantify document formwork with intelligent, automated tools. It also coordinates adaptive and constructible reinforcement for any structure regardless of its complexity.

An important feature of Tekla Structures is an automated design-to-fabrication workflow. A model-based and fully digital workflow not only minimizes costly surprises and waste, but also improves efficiency and quality. It further ensures that the correct, error-free elements are delivered at the right place and on time.

Such digital workflows even help with streamlined project planning and execution. They allow project stakeholders to keep track of the progress and keep all parties of the supply chain well informed at all stages of the project. Utilizing the status information in the digital model is in fact a clear and effective way to coordinate the project and ensure its progress according to the predetermined schedule, as we can learn from a truly pioneering concrete project currently under construction in London.

One Nine Elms: A Case for the Constructible

One Nine Elms is a skyscraper development under construction on the south bank of London’s river Thames. Upon completion in 2022, the development’s two towers (with 57 floors and 43 floors respectively) will combine luxury apartments, retail outlets and a five-star hotel. The project- two visually striking glass towers – the lower tower, which features the development’s hotel, is 160 meters high whereas its counterpart reaches 200 meters, making it the tallest residential building in Western Europe.

The One Nine Elms developers chose a top-down method for constructing the buildings’ three-floor basement for time and cost efficiency. “When the drawings for reinforced concrete construction are created in 2D, the chances of missing certain sections of rebar increase. This can cause huge time delays and additional costs for making the fixes”, says Solve Structural Design Technical Director, Barry Penniston, “3D modelling, such as that provided within Tekla Structures, allows for the proposed drawings to be checked quickly and accurately, ensuring full continuity before any concrete is cast.”

The re-bar design challenges were compounded by the fact that the core base raft for one of the buildings was constructed under very tight conditions. This meant that all equipment and materials had to be supplied through two small mole holes. With a Tekla 3D model serving as the single source of truth, the rebar detailers were able to identify and design around the congested areas, as well as avoid costly rebar clashes. This minimized the cutting and changes typically associated with a project of this nature, which in turn kept delays to a minimum and meant on-site work was safer. All this was especially critical amid the tight conditions and considering the size and complexity of the subsequent continuous pour for the taller tower.

Many similar projects in India and around the world by other construction industry leaders have amply demonstrated the value advantage of using 3D tools in general and constructible BIM in particular in delivering concrete-based projects faster and within budgets. The business case of enabling fully digital and model-based workflows for construction projects is well established today, and the gains are far too significant to be overlooked by anyone – least of all the forward-looking construction companies in India.

For further information,

visit: www.trimble.com