Lotte World Tower

The South Korean government, in the past decade, provided a great deal of assistance for a number of tall building projects in lieu of inner city regeneration endeavours. One such project was Lotte World Tower at 1,820 ft. (555m) height located in Seoul, South Korea, stands as the first super tall building with 123-storeys and more than 1.8 times taller than the previous tallest building, located in the nearby city of Incheon. The building culminated in December 2015 and the tower ’s topmast, christened as the “Lantern,” was completed in March 2016. Designed by architects Kohn Pedersen Fox Associates and structural engineers Leslie E. Robertson Associates (LERA) of New York, the $2.5 billion tower and adjacent development features a variety of usages, including office, retail, hotel, officetel (a combination office and apartment common in Korea), parking, museum and observation space.

|

|

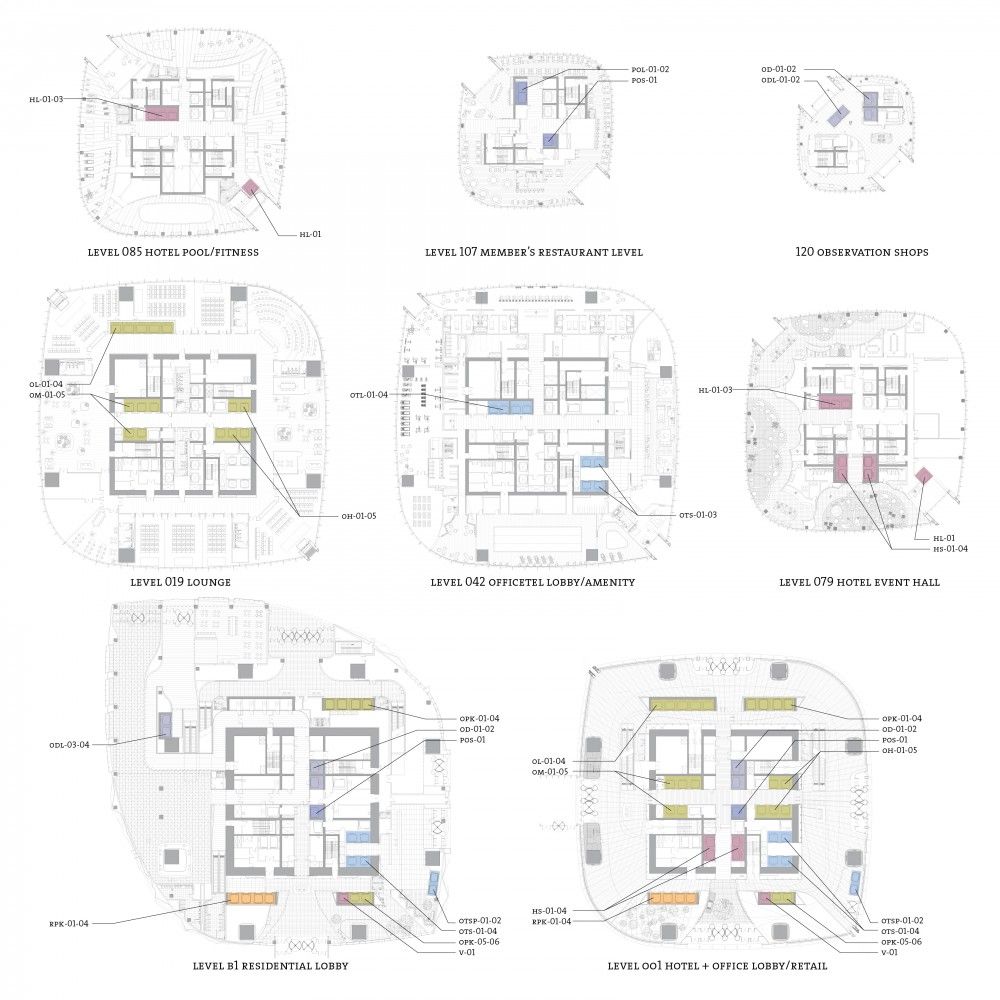

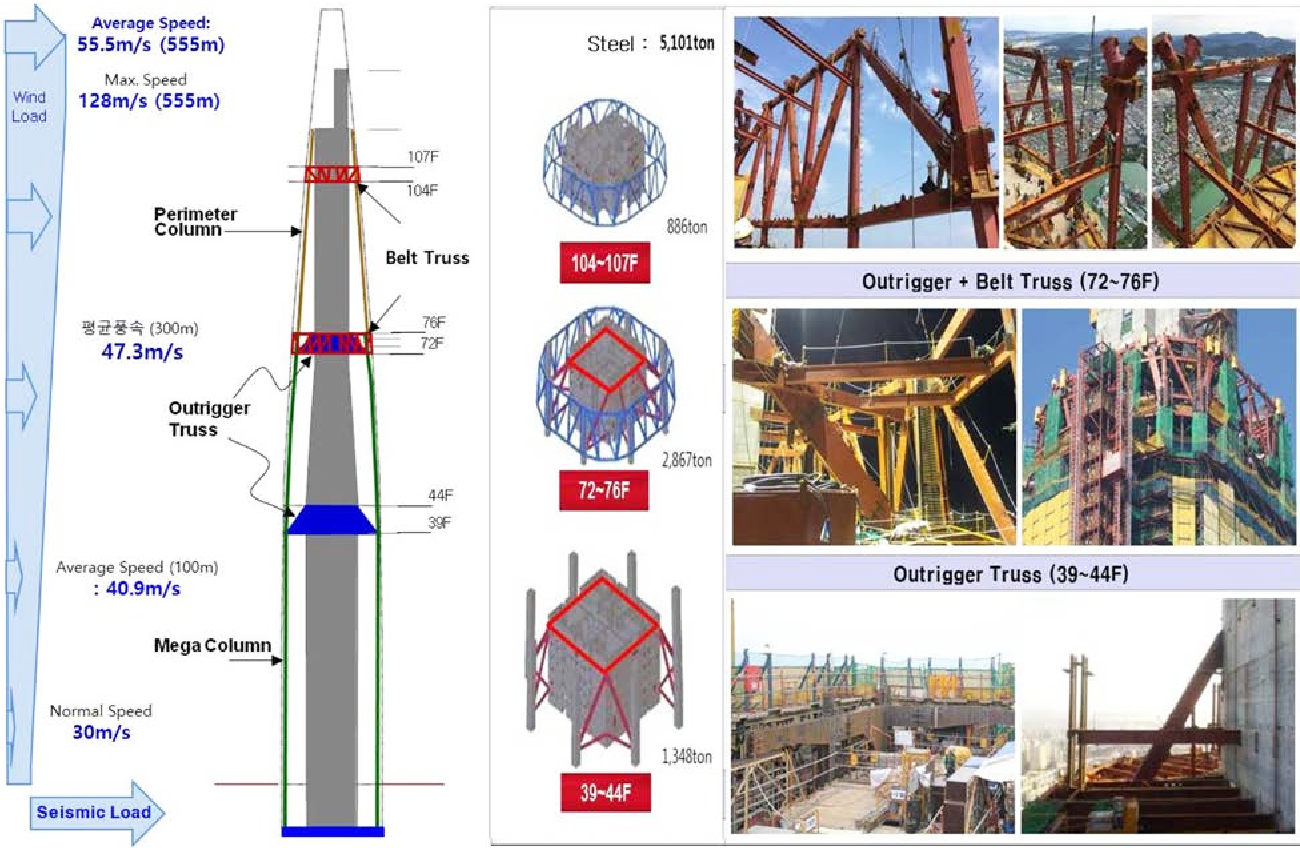

Building Illustration The tower ’s struc tural system is made of a gravity-resistant and a lateral force resistance system. The tower has a tapering shape with sloping concrete core walls in the middle third of the building and columns sloping in two directions which creates a unique environment on every floor. The office and officetel floors, from the ground level to 71 level occupies the majority of the tower, are steel framed with a slab-on-truss deck. The Hotel floors from levels 87 to 101 are concrete flat slabs with drops. The tower consists of a diagrid structure at the top of the building contains premium office, museum, and observation floors, which are also steel framed with a slab-on-truss deck. With piles reinforcing the ground, the tower sits on top of a 21.3ft. (6.5m) thick mat. Conforming to Korean building regulations, these piles are not connected to the mat. The tapered shape of the building was effective at minimizing wind loads but it led to challenging structural complexities. The primary lateral load and gravity system of the tower consists eight concrete mega-columns, concrete core walls, a series of outriggers and belt trusses located at the mechanical, refuge, sky lobby and hotel amenity floors. |

The diagrid “lantern” structure is transferred by the belt trusses to the column configuration of the hotel floors, as well as the columns of the hotel floors to the mega-columns at the officetel and office floors. For tying the perimeter mega-columns to the concrete core, only two levels of outriggers were needed to control the tower’s drift and lateral accelerations due to wind loads.

|

The 10 ft. 9” X 10 ft. 9” (3.3m X 3.3m) mega-columns at the ground level (unbraced for the first eight levels) are comparatively small compared to other towers of similar height and even qualify as slender members. Higher up the building, the hotel floors are supported by perimeter steel columns that are spaced at the module of the hotel room partitions and transferred through belt trusses. LERA with the architects worked closely to balance out the structural efficiency gained by adding columns and the need to preserve open floor plans. A multitude of structural designs were studied – a system of concrete mega-columns with relatively small intermediate steel columns at the perimeter ; a system of long-span spandrels with clear spans between concrete mega-columns; and a combination of the two. Lotte, the owner, selected a system of long-span spandrels for the office and officetel floors, with spans of up to 80ft. (24.5m) between mega-columns. The building |

corners have long-span spandrels cantilever 46ft. (14m) beyond the mega-columns while bending to follow the building’s curved floors. These corners posed significant challenges for meeting the stringent deflection and vibration floor criteria. To overcome this hurdle, LERA designed a series of 1 storey high deflection control posts at every other floor, aligned with the cladding mullions.

|

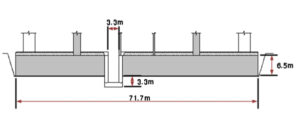

Foundation As per a geotechnical repor t, the soil beneath the foundation is made up of soft and hard rocks. The permissible strength bearing of these rocks is 3,000 KPa which is suitable for supporting the building weight. Nevertheless, the area contained fault zones and shear zones which might have lead to settlement and to prevent it, ground strengthening piles were put into use. The piles of 1.0m. dia. were installed using PRD (Percussion Rotary Drilled) method preventing the settlement of the mat foundation and also the uneven settlement under the RC core walls and the megacolumns. To separate the mat foundation from the piles, a sand cushion was installed at the upper part of the piles. With the help of soil engineering specialists, the 6.5m thick mat foundation was designed considering static and dynamic soil springs. This massive foundation consists of 4,200 tons of steel reinforcement, including those with a diameter of 5.1 cm, and 80,000 tons of high strength concrete. In the building’s surrounding area, 1m thick and 27m long cut off collars were installed through the bedrock in order to keep underground water from leaking in. Lateral Load Resisting System As per the design need, lateral loads on the building are resisted by RC core walls, outriggers, belt trusses and megacolumns. A study was conducted which resulted in determining two sets of outriggers and two sets of belt trusses to be the most optimal fixes for the lateral load resisting system. Perimeter frames of typical floors were also changed to a long spandrel girder system connecting the megacolumns. |

Steel box B – 1600 X 500 X 80 X 20 was used for outrigger diagonal members. As, they mainly support axis loads, the web thickness of the steel box was increased to 80mm and the flange thickness was decreased to 20mm. The top chord of the outrigger penetrated the RC core wall and reach horizontal truss member on the other side so that horizontal forces in the RC core walls can be easily transferred to the outrigger trusses.

Sustainable Features

The Lotte World Tower incorporates sustainable features of the LEED Gold standard.

- Greening of Rooftop

Lower-floors insulation through greening of rooftop for reducing heating/cooling load and environmental pollution.

- High Insulation Glass (Low0E)

Reduction of heat loss in winter and blocking of heat in summer.

- Recycling of Heavy Water and Rainwater

Operation of heavy water treatment facilities (1,200t) and rainwater storage tanks (1,900t) for recycling domestic sewage

- High Efficiency Equipment and Apparatus

These facilities have been incorporated to achieve savings of 30%.

- Wind Power Generation

Wind power generator installed in upper floors and around the complex to generate electricity.

- Solar Heat Collector

Collection of solar energy in rooftop to be used for heating and hot water supply.

| World’s Tallest Building Rank | 5th |

| Annual Visitors | 1,300 Million |

| Attached Glass Windows | 42,000 Pieces |

| Awards: 2017 | LEED Gold Level Certificate/USGBC, US Green Building Council 2017 The highest glass-floor observation deck, the Sky Deck/GUINNESS WORLD RECORDS 2017 |

Reference

- https://global.ctbuh.org/resources/ papers/download/2504-challenges[1]and-opportunities-for-the-structural[1]design-of-the-123-story-jamsil-lotte[1]world-tower.pdf

- https://www.lottepnd.com/en/tower/ safety/method.do#:~:text=This%20 massive%20foundation%20 consists%20of,times%20more%20 concrete%20was%20used.

- https://w ww.structuremag. org/?p=11393

Lakhta Center

Lakhta Centre, situated in the north western region of Lakhta in Saint Petersburg, Russia; is an 87-storey skyscraper, standing 462m (1,516ft.) tall infront of Baltic Sea, is the tallest building in Russia, the tallest building in Europe, and the fourteenth-tallest building in the world. 30th October 2012 marked the beginning of the iconic building’s construction while it reached its zenith on 29th January 2018. Designed for large-scale mixed-use development, consisting of public facilities and offices, the project was first undertaken by RMJM, it was then continued by GORPROJECT (2011-2017) based on the RMJM Concept (2011) under the main contractor, Rönesans Holding. The unique spear-shaped tower, featuring a tapering, rotating design, is intended to be the new Saint Petersburg headquarters for Russian energy company, Gazprom.

Structural System

The structure of the tower is shaped around a central circular core wall with 5 equal wings/petals that rotate 90 degrees from the base to the top of the spire which means none of its 89 floors repeat and tapers relative to the tower’s structural center. The overall dimension of the tower is approximately 213.26 ft. (65m) at the base, 220.8 ft. (67.3m) at level 17, 91.2ft. (27.8m) at level 86, and diminishes at the tower pinnacle at 1515.7ft. (462m).

|

- Reinforced Concrete Core Wall System

RC core + Composite Steel Outrigger connected to Composite Columns at 5 locations along with the building height. (17-18, 33-34, 49-50, 65-66 and 83)

- Box Foundation System

Consisting of 3.6m thick bottom raft (Bottom Flange @ TOS EL = 17.65m) connected to 2m thick slab (Top Flange @ TOS EL : -4.65) with Fin walls to provide very stiff foundation box section to distribute the tower loads to the 2m dia. piles that extend to 65m and 55m within and outside the core area respectively.

Façade Construction

The façade comprises of 1,550 metric tons of aluminium and 1,100 metric tons of steel, whereby the outer façade has an area of approx. 73,000m² and the inner façade approx. 25,000m². The latter is mainly made of glass walls for the inner closure of the entrance. The elements of the outer façade are mainly in the shape of a parallelogram; at 4.2 x 2.8m, they weigh up to 790 kg. In total, there are over 16,500 different and partly bent elements. The aluminium-glass façade is fastened to steel girders in the entrance area; these girders span two storeys despite the twisting of the floor slabs. A total of six different types (WT1 – 6) were produced for the tower façade’s construction. The main façade is made up of the WT1 glass façades of the office areas, the WT2 glass façades of the atriums and the WT3 of the corner façades with stainless steel casing.

|

|

High Grade Sustainability The Lakhta Center’s energy-efficient design highlights advanced heating, waste, and lighting systems and an “intelligent facade” that reduces energy consumption earning Platinum certification. Rain water is recycled for irrigation, and the building uses a pneumatic-vacuum waste-disposal system. Inside, infrared radiators replace conventional heaters; excess heat generated by the building’s plumbing equipment, mechanical and electrical equipment is channelled into the heating system. A computerized LED-lighting system maximizes light energy, both inside and out. |

| Height | 1,516ft. (462m) |

| Floors | 87 above ground, 3 underground |

| Cost | 117 Crores USD |

| Elevators | 40 |

| Opened | 2019 |

Reference

- https://redshift.autodesk.com/lakhta-tower/

- https://www.skyscrapercenter.com/building/lakhta[1]center/12575

- https://www.researchgate.net/publication/349076674_The_Structural_Engineering_Design_And_Construction_Of_

The_Tallest_Building_In_Europe_Lakhta_Center_St_Petersburg_Russia

Tuhina Chatterjee

Associate Editor

Civil Engineering and Construction Review