By Amrita Batra

Construction is an essential component of the infrastructure and architecture development of all other industries. It is a determinant of how and where people live and work. It is only recently beginning to undergo a much-required modern transformation. With the growing digitalization of human interactions and exponential decrease of the timeframe at which people are embracing new technologies, the fourth Industrial Revolution is expected soon.

The construction job site is now prepared for major changes that allow efficiency, safety, process upgrading and new tools. As Internet of Things (IoT) continues to become more pervasive, it is having a greater impact on the construction industry. IoT allows every stakeholder to understand the steps at every stage of the construction process in real-time, from planning to actual construction, post-construction and how the building is operated during service.

What is IoT?

Internet of Things (IoT) refers to the concept of basically connecting any device with an on and off switch to the Internet (and/or to each other). The technologies behind the IoT have existed for several years in the construction market. Features like remote access, office-to-field data exchange, cloud computing and data storage are not new to the construction industry. Though it has been available for some time, not all construction contractors have invested in these new technologies; whereas in consumer markets, these technologies are still fresh and ground-breaking.

IoT And Construction

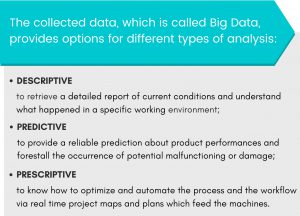

The IoT Platform provides construction equipment manufacturers and the end-user contractors with analytics and reports about several facets of their tasks and assets. This helps to enhance the decision-making process and attain the best management of resources, fleets and workers.

In the construction industry, the key to IoT is sensors. Sensors, installed with the capability of with the capability of sending and receiving data, allow capturing information required to improve results with real-time data about the site and the workforce. The IoT is allowing for the positioning of low power sensors that communicate cost-effectively. The sensors lets the platform reproduce a digital detailed representation of the product itself. Consequently, experts based anywhere in the world can provide monitoring, troubleshooting, and/or repairs without needing to be physically present at the worksite or contractor’s location.

In addition, the data collected from IoT-enabled products and systems provide detailed information on their most useful and most ignore features. IoT-enabled construction equipment, through the historical data, can help shape patterns of information to better understand the requirements of the customer and contractors, the environment in which they operate, and ultimately, offer appropriate solutions as per their necessities at https://dirthammers.com/terlemek-kilo-verdirir-mi/.

The IoT platform provides detailed information that can be selected according to the need at the time. Following are some of the tangible and vast applications of IoT in construction industry:

Safety And Security

Some of the biggest challenges encountered on a construction job site are theft and safety. As construction sites are vast, relying merely on manual security isn’t viable or practical. IoT security strategy for a construction site can work on averting invasion and quick discovery as well as recovery from undesirable happenings. Autonomous vehicles and UAVs (Unmanned Aerial Vehicles) like drones are being favoured for site monitoring, which are suitable for monitoring and surveillance of vast spaces. These drones can gather accurate aerial images and survey maps of a site. Using IoT enabled tags, any material or theft of items is easily resolved as these sensors will notify the current location of the materials or item. Attaching IoT enabled tracker to such assets provides higher accuracy and convenience. The data collected from these trackers are easily actionable and dependable.

Augmented Reality in Construction

Machine Control And Maintenance

Several human-operated heavy machines are a part of construction work. This task can be simplified through IoT; with sensors, these machines can work more precisely and with minimal human effort. Further, equipment condition and maintenance related issues can also be supervised uninterruptedly through IoT sensors. With the availability of real-time information, it becomes possible to know the status of every asset, to schedule maintenance stops, or refuelling and turn-off idle equipment. Beyond this, sensors can be also used to monitor materials’ condition, like the suitability of the temperature, or humidity of the item/environment, handling issues, damage and expiration.

IoT is the Future of Construction Sites

IoT Cycle

Augmented Reality (AR)

With the use of AR, operational instructions, or navigational and driving information are witnessed over the IoT in real time and are overlaid onto the real-world view. Through IoT, inanimate objects such as smart glasses can be connected to the internet. Such devices include Google Glass and Microsoft HoloLens. These technologies are currently being applied to planning and modelling step of construction. Smart-glasses can be used to reproduce a suite floor with all the furnishings; this can be peeled back layer by layer, to study and plan the intricacies of the work behind the walls. Clients are also using the smart-glasses for sales so that residents get an immersive view of what their new facility feels and looks like. Employees are also empowered on and off the job site since through connected smart-glasses they can view work instructions while performing specific tasks, potentially improving their performance.

Building Information Modelling (BIM)

Building Information Modelling (BIM) can be optimized through generative design, prediction of cost overruns using appropriate features, risk mitigation through the identification of the biggest risk factors on a job site, application of reinforcement learning to project planning, autonomous and semi-autonomous vehicles, labour deployment optimization, off-site construction and post-construction. Computer models that have been used to direct real-life construction can, in turn, be updated by sensors placed in the buildings that have now been constructed. The sensors can send back information on the way that materials are affected by changing climates and the passage of time. They can supply information on possible changes in energy efficiency in roofing, how structures behave when there are earth tremors, or how a bridge bends under the weight of passing traffic.

Thus, IoT is here to stay. It is the future, and for many it is the present. In the construction sector, the success of technology that facilitates construction contractors to complete projects more accurately based on their own historic production data and get their jobs completed faster, more accurately, and more efficiently using intelligent interconnected technology, has raised customer expectations.