|

Dr. Narayan V. Nayak |

|

Siddhesh R. Kamat Mhamai

|

|

|

Vivekanand Laxman Harikantra |

Shridhar A. Behare |

When considering durability of concrete, chloride attack is the most imminent enemy. In the presence of oxygen and water, chloride attack corrodes the steel reducing the strength of the structure drastically.

Chloride ion (Cl-) is formed when the element chlorine gains an electron or when a compound such as hydrogen chloride is dissolved in water. High concentrations of chloride ions in concrete, due to their electro-chemical nature, break down the passive layer of reinforcing steel, without the need to drop the pH levels. Corrosion takes place as the chloride ions react with steel and the surrounding passive material to produce a chemical process which forms hydrochloric acid. The hydrochloric acid reacts with the steel reinforcement, whereby the volume of steel is increased due to corrosion leading to concrete cracking, spalling and eventually failure of concrete.

There are two main sources of chloride ions, one is from the concrete making materials, and the other from the surrounding environment. The first could come from aggregates, admixtures, and from water used for making concrete and the second comes mainly from the concrete being exposed to marine environment such as sea salt spray, direct seawater wetting, concrete being in contact with soils that are rich with chlorides deposits or it can come from de-icing salts and use of chemicals. It is by the process of diffusion that chloride penetrates the concrete. The main problem involving the corrosion of the steel is the spalling of the concrete cover. The oxide resulting from the corrosion is very porous and takes up to 10 times the volume of the steel which causes the break-up of the concrete.

RCPT Test

The Rapid Chloride Permeability Test (RCPT) is a test that uses the total charge, driven by an applied electric field of 60 Volts, passing through a 2-inch thick and 4-inch diameter concrete sample over a period of 6 hours, as an index of the concrete permeability. This test has been standardized as ASTM C 1202/AASHTO T 277. The specimens are vacuum-saturated with de-aired water before testing. An electrical current is conducted from the power source by placing one end of the sample in a 0.3 N NaOH solution and the other end in a 3.0% NaCl solution. Although the test is intended as an indirect measure of the concrete pore system network, anything that changes the concrete resistivity will change the results. For example, certain admixtures such as calcium nitrite change the pore solution conductivity and change the results. Likewise, conductive fibers or aggregates that contain hematite can change the concrete electrical resistivity without changing diffusion properties. Changes in the vacuum pressure used during saturation or other specimen conditioning prior to testing can also change the sample resistivity due to the effect of the degree of saturation of the tested specimen on the measured result.

RCMT Test

The Rapid Chloride Migration Test (RCMT, NT Build 492) uses electrical voltage to accelerate chloride migration. The test specimen shall be 4 inches in diameter and 2 inches thick, and prior testing the specimen is vacuum-impregnated with saturated lime solution as described in NT Build 492. After the specimen is prepared, the concrete is exposed to a 10% NaCl solution on one side and a 0.3 N NaOH solution on the other. The test starts by measuring the initial current through the sample for an applied 30 volts.

Fig. 1: Schematic RCMT Set UpThe initial and final current through the specimen and specimen temperature are measured. After the test duration is completed, the concrete specimen is split open and a 0.1M silver nitrate reagent is applied to the sample. The chloride penetration depth, as evidenced by the precipitation on the specimen of silver chloride, is measured at least seven depths to an accuracy of 0.1mm (0.0039 inch). The surface chloride content can optionally be measured by cutting a 5mm (0.197 inch) concrete slice on the surface exposed to the chloride solution and measuring the acid-soluble chloride content in the slice. This chloride content can be used to get information on the concrete sample chloride binding capacity.

Use Of Secondary/Supplementary Cementitious Materials (SCMs)

The addition of SCMs to concrete can substantially increase the concrete’s resistance to chloride ingress. The use of SCMs can improve concrete’s durability, resistance to degradation due to multiple mechanisms, and strength gain behaviour. SCMs have two primary forms of reaction that influence the properties of the concrete. The hydration and chemical reactivity of SCMs are functions of their compositions, with many SCMs showing varying ranges of each type of reactivity.

Latent Hydraulic Reactivity

The material will react with water to form strength-bearing phases, with or without the presence of Portland cement. SCMs of this form typically will contain both calcium and reactive silicates.

Pozzolanic Reactivity

The SCMs will react chemically with water and the hydrated cement paste to form additional strength-bearing phases and cause a densification of the microstructure. Pozzolanic materials are typically siliceous in nature and need not contain lime-bearing phases. The reaction rates of SCMs impact their influence on the pore structure, and as a result reducing the rate of chloride diffusion through concrete. For the purpose of this study, the following materials were used in concrete and the test results evaluated to study the chloride migration characteristics of concrete:

- Ground Granulated Blast Furnace Slag (GGBS)

- Fly Ash

- Alccofine 1203

Ground Granulated Blast Furnace Slag (GGBS): Ground granulated blast-furnace slag, is a by-product of steel production. Slag is primarily composed of CaO, SiO2, aluminum oxide (Al2O3), and magnesium oxide (MgO). When used as part of a Portland cement concrete, slag reacts with both the water (latent hydraulic reaction) and the hydrated cement paste (Pozzolanic reaction), resulting in a more refined microstructure than that of a plain Portland cement.

Fly Ash: Fly ash is a by-product of coal combustion and composed primarily of silicon dioxide (SiO2) and calcium oxide (CaO). When added to concrete, fly ash reacts with the hydrated cement paste in a primarily Pozzolanic reaction; the result is a denser microstructure over time.

Alccofine 1203: Alccofine 1203 is a new generation, ultrafine, low calcium silicate product manufactured by Counto Microfine Products Pvt. Ltd. (CMPPL) – a joint venture between Ambuja Cement Limited & Goa based, Alcon group. The production facility is at Pissurlem Industrial Estate.

Concrete Mix Design

Concrete trials were conducted with the following proportions: a). OPC alone.

- OPC + Fly Ash, replacing 20%, 35% , 40% & 60% of Fly Ash in cementitious

- OPC + GGBS, with replacing 35%, 50%, 70% & 90% of GGBS in cementitious

- OPC + Alccofine 1203, with replacing of 5%, 15%, 25% & 35% of Alccofine 1203 incementitious

- OPC + Fly Ash + 5% Alccofine 1203, replacing 20%, 35%, 40% & 60% of Fly Ash in cementitious

- OPC + GGBS + 5% Alccofine 1203, with replacing 35%, 50%, 70%& 90% of GGBS in cementitious

- OPC + Fly Ash + 3% Alccofine 1203, replacing 20%, 35%, 40% & 60% of Fly Ash in cementitious

- OPC + GGBS + Alccofine 1203, with replacing 35%, 50%, 70% & 90% of GGBS in cementitious

The Test Method

The test method used to find the chloride ingress resistance of the concrete was the NT Build 492 test. The NT Build 492 test comes from the Nord Test (Based in Finland) family of test methods. This is an alternative to ASTMC1202, and the result is a chloride migration coefficient from non-steady state migration experiment, DNSSM x10¯12m2/sec, that can be used to access the quality of concrete. NT Build 492 is adopted widely in Europe and the USA. It is also fully adopted in China, as the National Standard GB/T50476. Apart from the above some experiments were also conducted by using the ASTM C1202 test method, with the mix proportion given in the Table 1 for Sr. No. 18 to Sr. No. 29, the results of the tests are presented in figure 5.

Difference Between ASTM C1202 Method And NT Build492

The NT Build 492“Chloride Migration Coefficient from Non- Steady State Migration Experiments” (RCMT) test method is different from the widely used ASTM C1202 test, the ASTM C1202 test is often criticized based on a report from a FHWA (Federal Highway Administration, U.S. Department of Transportation) study by Whiting[1].

The fundamental differences between the NT Build 492 “Chloride Migration Coefficient from Non- Steady Sate Migration Experiments” and the ASTM C1202 “Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration” (RCPT) test method are:

- RCPT test fundamentally is simply a conductivity test or inverse- resistivity test and in spite of it often being referred to as Rapid Chloride Permeability Test, it does not measure the “permeability” or “chloride diffusion” of concrete[2].

- High current flow in RCPT test results in heating of the sample and solution during the 6 hours test, raising the measured conductivity, thus a better quality concrete looks worse than it would

- The transport of ions in concrete depends on the pore structure of the concrete, while the electrical conductivity of concrete or RCPT results depend upon both pore structure and electrical conductivity of the pore solution, which in turn is determined by composition of the pore

- It is not correct to use electrical conductivity of concrete or RCPT results to rank rapid chloride permeability of concrete containing supplementary cementitious materials[4].

- ASTM C1202 states in clause 1, that this test method is applicable to types of concrete where correlations have been established between this test procedure and long term chloride ponding procedures such as those described in AASHTO T 259. In other words, establishing correlation with the ponding test is a prerequisite for using RCPT. How many laboratories actually conduct the classical 90-day soaking test and establish the correlation with RCPT, is not known.

- High water reducing admixtures work on the principle of electrical polarity to create electrical This may cause substantial changes to the overall electrical conductivity of concrete. It has been reported that different types of water reducing agents added to otherwise identical concrete mixes caused variance of up to 700 coulombs in total charge passed in RCPT.[9]

- On Precision and Bias, ASTM C1202 states that the single operator coefficient of variation of a single test result has been found to be 12.3%. The variability of results between two properly conducted tests by the same operator could be as much as 42%. The multi laboratory coefficient of variation of a single test has been found to be 18.0%. Therefore, results of two properly conducted tests in different laboratories could varyby as much as 51%.

- RCMT test is a non-steady state migration test, developed by Tang and Nelson[5]and adopted as NT Build 492 involves measurement of the depth of chloride ingress under applied DC potential (voltage and time of the test are determined from an initial current measurement).

- In RCMT for avoiding the influence of other carrying ions, the non-steady state migration coefficient is calculated from the actual chloride ion penetration measured from visible silver chloride precipitation that is developed after application of silver nitrate solution on the axial split specimen on completion of the test.

- The results of RCMT are not influenced by concrete pore fluid conductivity and depth of chloride penetration is measured

- The calculated diffusion coefficient can be used in service life prediction models[2].

Note: A detailed study on RCPT as per ASTM C 1202 can be found in the article – “Revisiting Rapid Chloride Permeability” by Milind Joshi and Siddika Mapari, POV, ICI 2010.

Brief Description Of Test (NT Build 492)

This test procedure and test conditions can be briefly summarized as follows:

- Samples of 100mm in diameter and 50mm in height are

- Vacuum-saturation of the samples with limewater performed prior to the

- 10% (wt.) NaCl solution used as the catholyte and 3M NaOH solution used as the anolyte.

- Applied voltage in the range of 10 – 60 V, decided upon the value of the initial current, measured at a voltage of 30

- Duration of the test of 6 – 96 h, decided upon the value of the initial current, measured at a voltage of 30

- Correction factor of 2 V used in the equation for calculating the DNSSM, accounting for the polarization of the

- Temperature during the test between 20 and 25 °C.

Use Of NT Build 492 Test In India

In India awareness about designing concrete structures for durability is slowly increasing, the practice of specifying durability test for qualification of concrete mixes is also increasing at a slow rate. Currently, RCPT tests as per ASTM C1202 is specified for most of the metro rail projects as well as in many roads and bridges in the country, RCPT NT Build has been specified in the Bandra-Worli sea link bridge with limiting factor for pre-qualification of concrete mixes to be <2×10-12m2/sec. Considering technical advantages of the NT Build 492 test method over the ASTM C1202 method and as per the current trends in the industry, NT Build 492 is expected to replace the ASTM C1202 test in the years to come.

Test Results

All the experiments for RCMT were carried out at the R&D Division of Alcon Construction (Goa) Pvt. Ltd., at Goa, where the test facilities of NT Build 492 is available, the test results of the experiments are tabulated in the Table 1 below and the graphical representation are given in Figure 2, 3 & 4.

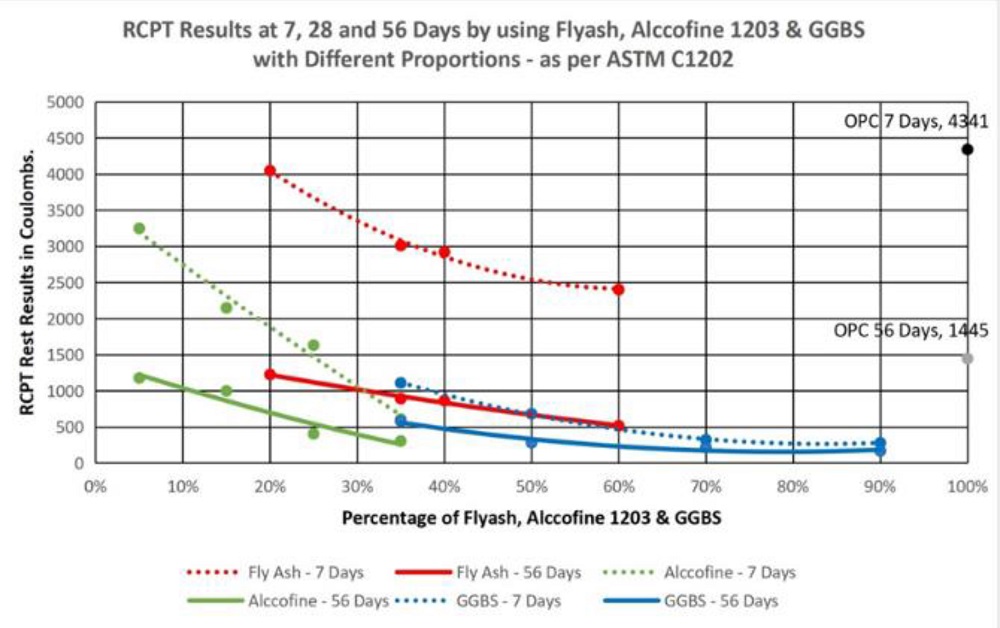

Fig. 2: RCMT Results at 7, 28 and 56 Days by using Different Proportions of Fly Ash, Alccofine 1203 and GGBS with Different Proportions

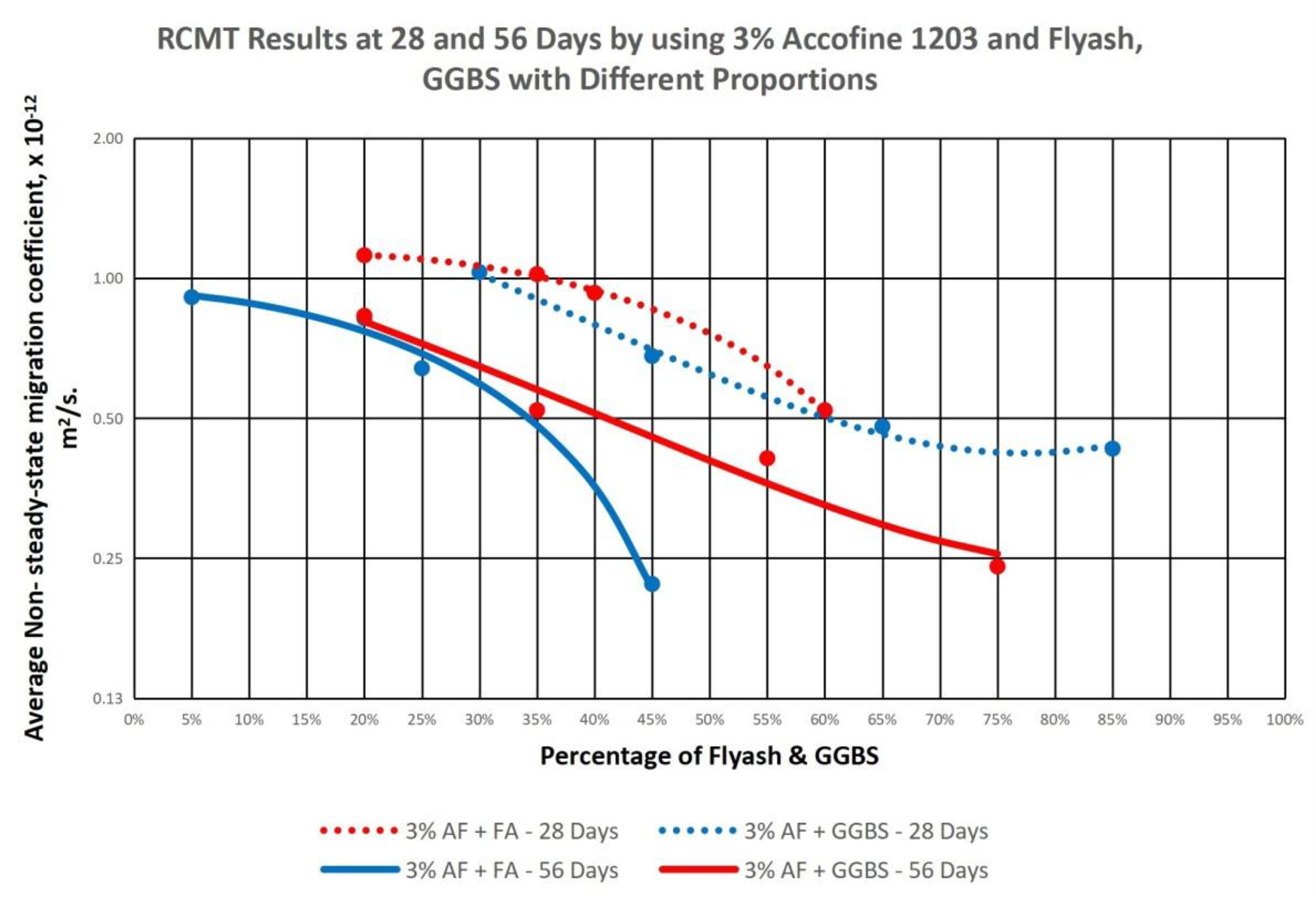

Fig. 3: 28 Days and 56 Days RCMT Results of Concrete with 3% of Alccofine 1203 and Fly Ash/GGBS in Varying Proportion

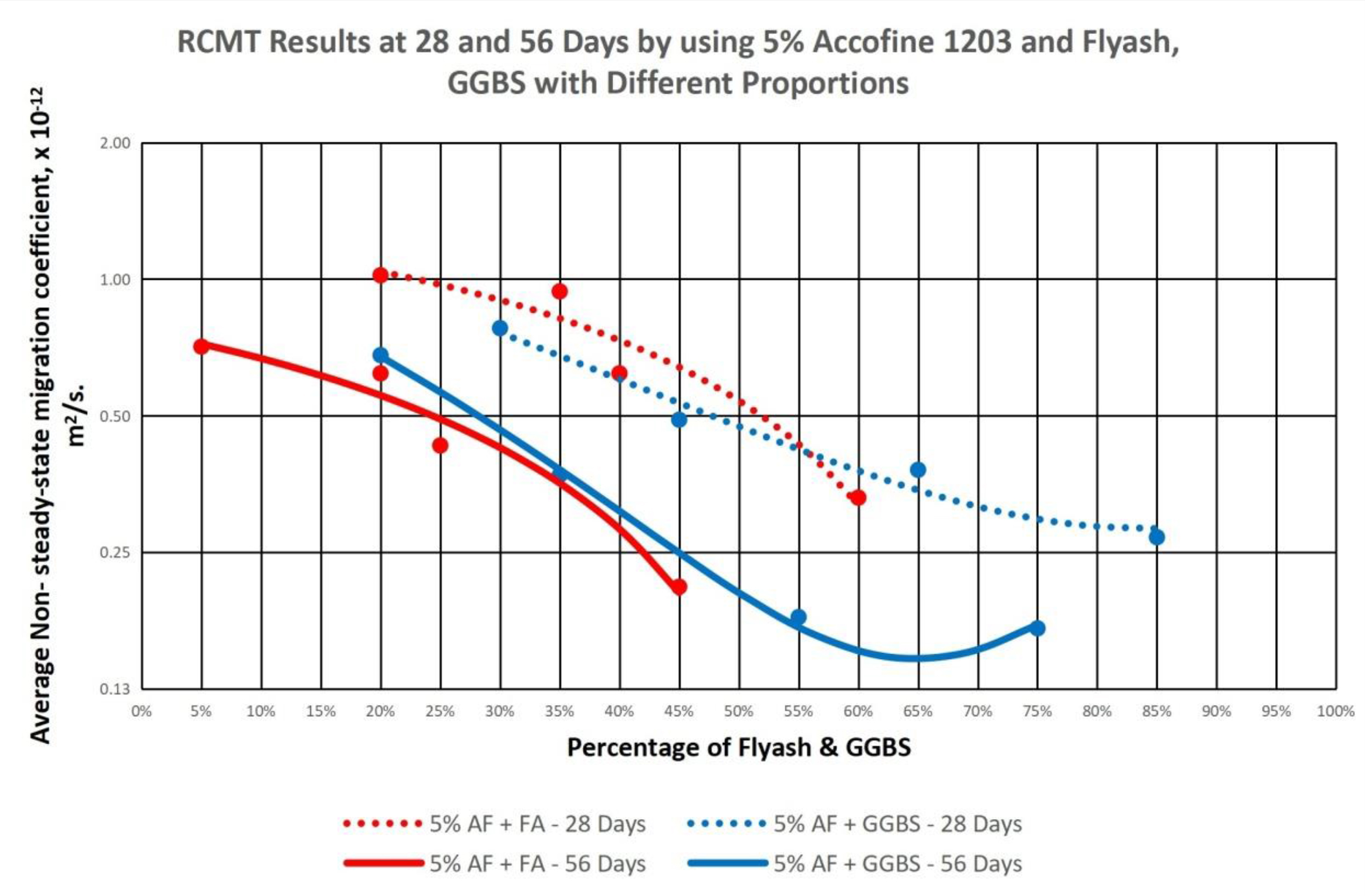

Fig. 4: 28 Days and 56 Days RCMT Results of Concrete with 5% Alccofine 1203 and Fly Ash/ GGBS in Varying Proportions

Fig.5: 7 Days and 56 Days RCPT Results of Concrete with Varying Proportions of Fly Ash, GGBS and Alccofine 1203

Interpretation Of Results

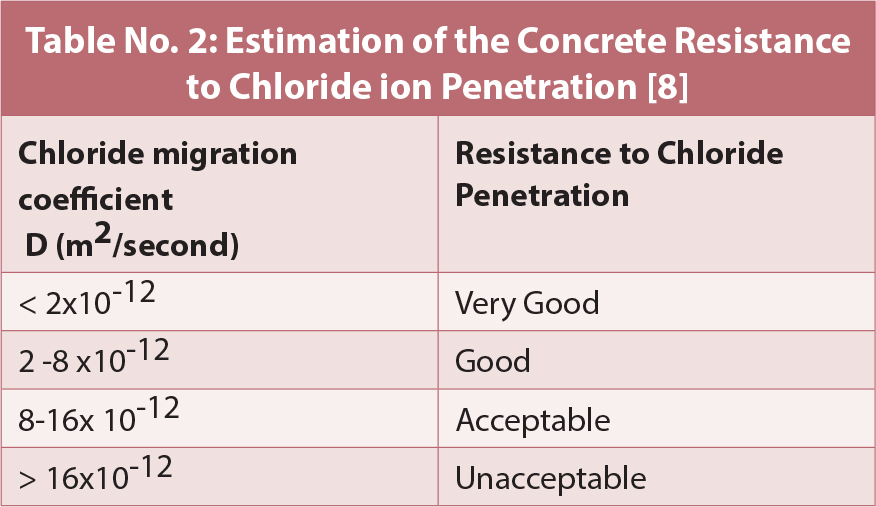

The chloride migration coefficient under non-steady-state (DNSSM) is used for evaluating the concrete resistance to chloride penetration, according to the criteria presented in Table No. 2.

| TPlease note that the results presented here are of single test for each different proportions of cementitious content (result is the average of three specimens), according to the results from Nordic round robin test between six laboratories, the coefficient of variation of repeatability of results is 9% and the coefficient of variation of reproducibility of results is 13% for Portland cement or for concrete mixed with silica fume and 24% for concrete mixed with slag [7]. The most effective SCM has been found as GGBS [10]. |

Conclusion

- RCMT value for fly ash concrete is very high at initial ages; the values are reduced at later ages of 28 and 56

- All the 56 days RCMT results of concrete with supplementary cementitious materials are less than 2 x 10-12m2/sec which relate to very good resistance to chloride

- RCMT values of concrete with only OPC are high and having least resistivity to chloride ingress as per the results of

- The results RCMT of OPC + GGBS/OPC + GGBS + Alccofine 1203 combination have the lowest results when compared to OPC + Fly Ash/OPC + Fly Ash + Alccofine 1203 combination, RCPT results in Figure 5 also show similar trends for OPC + GGBS combination.

- Addition of secondary/supplementary cementitious materials greatly improves the resistivity of concrete to chloride ingress, due to the improvement of pore structure of the concrete due to formation of additional calcium silicate hydrates in the hardened cement paste, which is able to resist the ingress of corrosion inducing

- RCMT values of concrete with 3-5% of Alccofine 1203 are the least of all the combination so far secondary/supplementary cementitious

- Highly durable concrete can be obtained by addition of 3-5% of Alccofine 1203 to OPC + GGBS & OPC + Fly Ash concrete.

- Concrete containing Alccofine 1203 which is a low calcium silicate based mineral additive is able to achieve the lowest values of chloride diffusion due to its unique particle size distribution resulting in enhanced hydration process, improved packing density of the paste component while lowering the water demand resulting in improved strength and durability of the concrete.

Acknowledgments

- RCPT tests were done at Goa Site of Gammon Engineers and Contractors Private Limited, Mumbai under the supervision of Mr Vivekanand

- Similarly, RCMT tests were done in Alcon Lab by Mr Siddhesh

- Results of both the tests were regularly monitored by Shridhar Behare.

- The whole investigations were done under the guidance of Dr V. Nayak.

References

- Whiting, , “Rapid Determination of the Chloride Ion Permeability of Concrete,” Final Report No. FHWAJRD-371/1 19. US Federal Highway Administration (1981).

- Development and Standardisation of Rapid Methods for Assessing the Fluid Penetration Resistance of Concrete,

- Hooton, D., Charmchi, G. and Karkar, E., XII International Conference on Durability of Building Materials and Components (XII DBMC), RILEM Proceeding Pro 96, Sao Paulo, 2-5 September 2014.

- Revisiting Rapid Chloride Permeability Test, Milind Joshi and Siddika Mapari, POV, ICJ, 2010

- Shi Caijun, Another look at the Rapid Chloride Permeability Test (ASTM CI 202 or ASSHTO T277)

- Tang, and Nilsson, L.O., “Rapid Determination of Chloride Diffusivity in Concrete by applying an Electrical Field,” ACI Matls. J., 89 (1) (1991)49-53.

- Standard test method for electrical indication of concrete’s ability to resist chloride ion phenomenon, ASTM C1202-97, American Society for Testing and Materials,

- NT Build 492 “Chloride Migration Coefficient from Non-Steady State Migration

- State-of-the-Art Report (Draft), RILEM TC 230 – PSC, RILEM Technical Committee on Performance Specification for Concrete

- Krieg, Willfried, Rapid Chloride Permeability Testing- a critical review,

- Concrete Engineering International, Summer2007, pp-48-49.

- Nayak, N. V., GGBS-The Most Effective SCM for Concrete-Civil Engineering and Construction Review, May 2020, pp-24-30.