B.E. Billimoria Moving To Precast Concrete Technology

BE Billimoria & Company is one of Indian’s leading firms of civil engineering construction contractors. Ranging from commercial, residential spaces to some of the most iconic buildings in the country, like the 316-metre Namaste Tower, are all among their project list. In addition, Billimoria has a precast project in Pune; a mass affordable housing for the Maharashtra police.

The company was established by Mr. Beji E Billimoria and Mr. Laxmidas K Kapadia in 1958. Mr. Jeet Kapadia, the Executive Director of Billimoria and the third generation of its founder, has recently started to follow his father’s footsteps to continue the family’s legacy in the construction business.

“We cater to all sectors, and work with some of the biggest real estate developers, governmental organizations, and corporates. Our main model is to give the right quality, because today in India, quality is the most important,” Jeet Kapadia says.

While many factors have contributed to Billimoria’s success since its foundation, the company has always been an innovator and true pioneer in the construction industry in India, from deployment of sophisticated building systems to the adoption of new construction technology, and brave pioneering of the precast building technology in India.

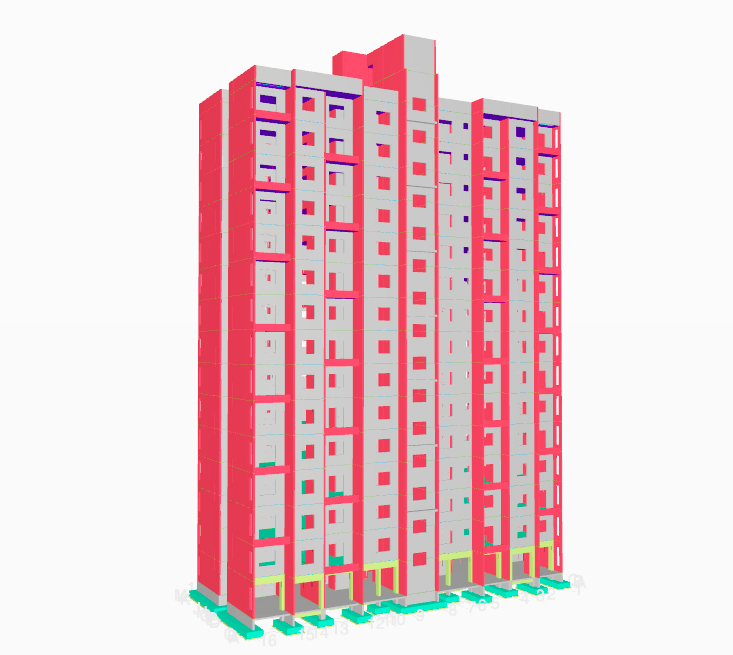

Billimoria factory in Pune, next to the Maharashtra Police housing project

A Growing Demand For High-Quality Affordable Housing

With the rapid economic growth and unprecedented pace of urbanization, there is a staggering demand for affordable housing in India. The government has already set an ambitious project to build 20 million affordable houses and 98 smart cities by 2022. Precast concrete building technology will be the key enabler for that mission, as it will not only ensure faster completion of a project but will also bring down its overall cost.

The traditional construction methods used in India require a high amount of labour for extended periods of time. This results in high costs, long duration of the construction project and quality variance due to human factors.

Precast concrete as a building method allows for more control over an entire building project. “As we increase the size of the projects, as we go to megaprojects, the amount of labour required is a big variable. We wanted to avoid that variable, and try to bring everything into a factory, so we can have quality control, cost control and timeline control. The only way to go for that was to go for precast,” Jeet Kapadia says.

The Best Way To Move Forward

Even though there are some obstacles hindering the growth of precast concrete building technology in India, in Mr. Kapadia’s opinion, precast is one of the best ways to move forward.

“Quality is the best benefit, because your slabs, beams, columns and walls are produced in a controlled environment. As a result, you are sure of the quality which you are getting. Speed is another big factor, because in the end, your expenditure depends on how soon you can complete your project,” Mr. Kapadia clarifies.

Confidence Rooted In A World-Class Partner

When evaluating suitable long-term partners among the many precast machinery companies, Elematic caught Billimoria’s attention.

“We went through a lot of companies who are doing precast, and felt with the increasing presence in India, Elematic will be able to support us the best in terms of after sales service, in terms of designing. We also felt that the machinery, which we got from Elematic will be for a longer period of time, and it will not give us a lot of trouble as compared to many of their competitors,” says Mr. Jeet Kapadia. Billimoria’s precast factory is located within a 116-acre site in Pune. The 2-acre factory includes production and storage yard. It produces slabs, walls and staircases. The capacity is approximately 1.5 million square feet of construction area in a year.

“We have three slab beds which are 120 meters long; for the walls, which are mainly load bearing walls, we have battery moulds and mechanical tilting tables; and moulds for staircase walls,” Jeet Kapadia tells.

The buildings feature a load bearing wall frame as their structural system.

I think the whole set up works well. The shuttle basically supplies the concrete bed, but the same shuttle can also go to the battery moulds. The logistics of that has been worked out very well by Elematic, as well as our engineers in cooperation with each other.” Mr. Jeet Kapadia continues. “Also, the way cranes were setup with the help of Elematic, in order to ensure the finished product was taken from the factory to the storage yard, the gantry cranes, the wagons, all of that, the whole setup has been excellent, and I’m very happy with that.”

“There were a few hiccups as in any of the projects we deal with, but I think overall, Elematic and Billimoria did a great job getting the products on site and delivering appropriately.”

With the service agreement, Elematic’s team has been on site to provide support for any quality or machine issues. For example, when the thickness of the wall elements needed to change from 170 mm to 160 mm, a swift solution was needed. Elematic’s experts helped to refabricate, ensuring that the production continued with 160 mm without much of a lag. “I think the slab quality, which we are getting right now is beautiful and definitely helps us gain more confidence in precast,” affirms Mr. Jeet Kapadia.

No Quality Compromised In The Maharashtra Police Project

The Maharashtra Police housing project is aimed to build affordable houses for retired police. The total land is 180 acres, of which Billimoria started to develop approximately 40 acres for 5,200 apartments, all of which must be completed within four years.

| The project proceeds with a floor cycle of 12 floors in 12 buildings in 12 days, basically a floor a day. | With precast, 90% of the building can be made in a controlled factory environment, free of weather dependencies and reduced labour dependencies. |

All buildings are of ground plus 14 stories. And our aim is to ensure after the ground floor, all the other floors are done with precast. The building design is pretty simple, there are only few differences depending on the flat contributions.” Mr. Jeet Kapadia says.

“We are very proud of the whole project, because we are doing it for the Maharashtra Police. We aim to give them affordable prices with good quality, the quality they deserve after serving the state. That is our intention and that’s what I’m proud of.”

| Solid slab production at the Billimoria factory with an Elematic slipformer machine. | Elematic provided all structural design to the Maharashtra project as well. The precast products used in the project include load-bearing walls, solid prestressed slabs and staircases |