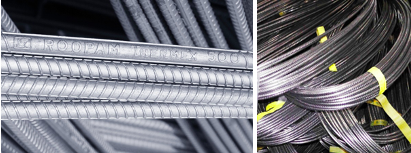

With the reputation of producing high quality steel

After three decades of rich experience in manufacturing of steel bars, ROOPAM STEEL has now come out with a never before kind of product, complying with every single technical parameter that contributes to the construction of structurally sound building, at an extremely affordable cost.

Roopam steels even in its initial stages, had gained reputation for using a high quality raw material to produce its steel. We have in house production of the raw material, i.e., M.S. Billets required to produce the TMT bars. We use continuous casting (Concast) technology to produce the M.S. Billet, where it undergoes the intense quality check in the well-equipped lab with spectrometer.

An Engineer’s Dream Come True

Thermex technology has cast a spell of magic over civil construction and engineering throughout the globe. The Thermex process is very sophisticated and precise technology that has been developed after years of trials and tests by engineers who were in hot pursuit of a low cost deformed steel bars to be used as reinforcement of concrete with guaranteed minimum yield strength of 500 N/mm2. With high ductility.

Steel bars that have undergone thermo process are widely preferred and far more dependable than those manufactured by any other methods.

High Temperature Resistance

Roopam Thermex Bars, unlike CTD bars, have a proven record in resisting loss of strength at high temperatures as experienced during fires. Roopam Thermex bars have high thermal stability at high temperature. They are a preferred choice in case of elevated temperature of 400-600°C applications.

Corrosion Resistance

Roopam Thermex Bars are more corrosion resistant than CTD bars. Cold working involved in CTD Bars leads to surface stresses and consequent higher rate of corrosion – the protective scale layer falls off during twisting. The Roopam Thermex process basically inhibits rate of scale formation and no cold working is involved.

Earthquake Resistance

Roopam Thermex bars are best suitable in high seismic zones due to the high fatigue resistance, ductility and elongation.

High Temperature Resistance

Roopam Thermex Bars, unlike CTD bars, have a proven record in resisting loss of strength at high temperatures as experienced during fires. Roopam Thermex bars have high thermal stability at high temperature. They are a preferred choice in case of elevated temperature of 400-600°C applications.

Corrosion Resistance

Roopam Thermex Bars are more corrosion resistant than CTD bars. Cold working involved in CTD Bars leads to surface stresses and consequent higher rate of corrosion – the protective scale layer falls off during twisting. The Roopam Thermex process basically inhibits rate of scale formation and no cold working is involved.

Earthquake Resistance

Roopam Thermex bars are best suitable in high seismic zones due to the high fatigue resistance, ductility and elongation.

Roopam Steel has always shown a huge appetite to assimilate the latest and globally proven researches in RCC technology. Our insistence on the specific 60 degree inclined uniform ribbed pattern has come from the study of intense research over the issue. Our belief in the research finding has been corroborated by the fact that all recognized civil bodies and even Thermex authority in India has now advised the adoption of this unique rib pattern.

It is because of the ability of Roopam Thermex to achieve such technical precision of the rib pattern that it has come to be recognized everywhere as the “Engineers’ Bar.”

Applications of Roopam Thermex QST bars

- Costal and marine environments which are susceptible to corrosion

- General purpose concrete reinforcement structures

- Bridges, flyovers, dams

- Industrial structures, high-rise buildings

- Thermal and hydel power plants

- Underground platforms in metro railways and rapid transport systems and many other areas

For further information,

visit: www.roopamsteels.com